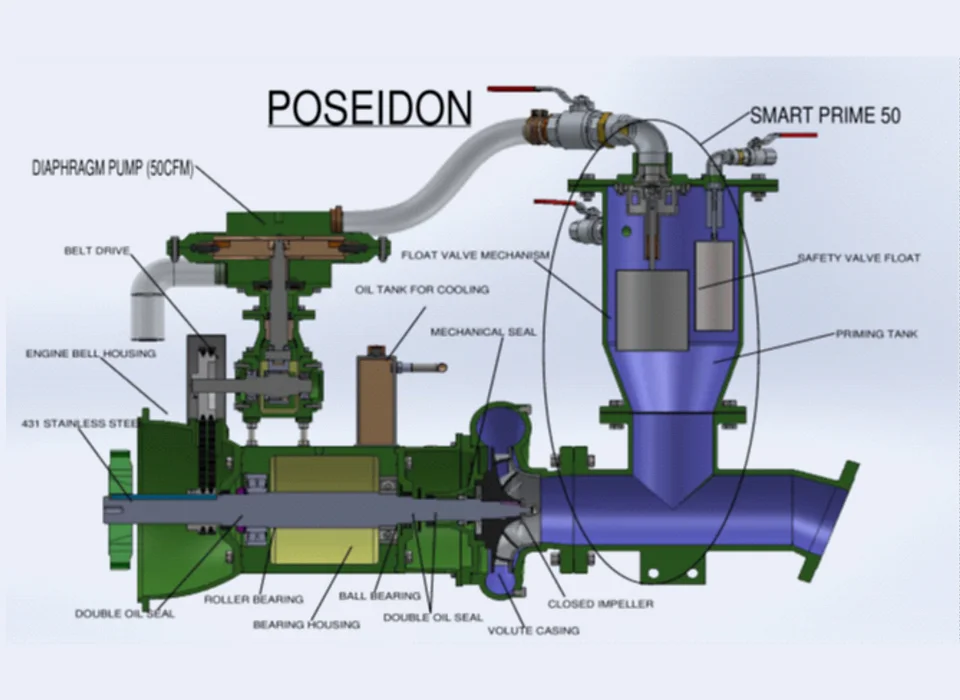

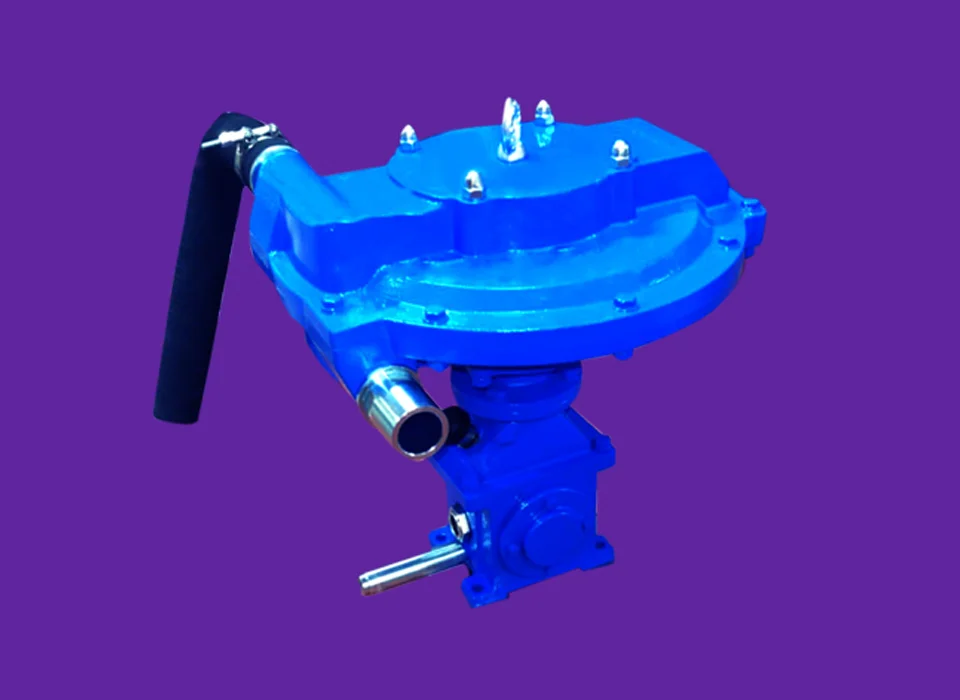

Smart prime

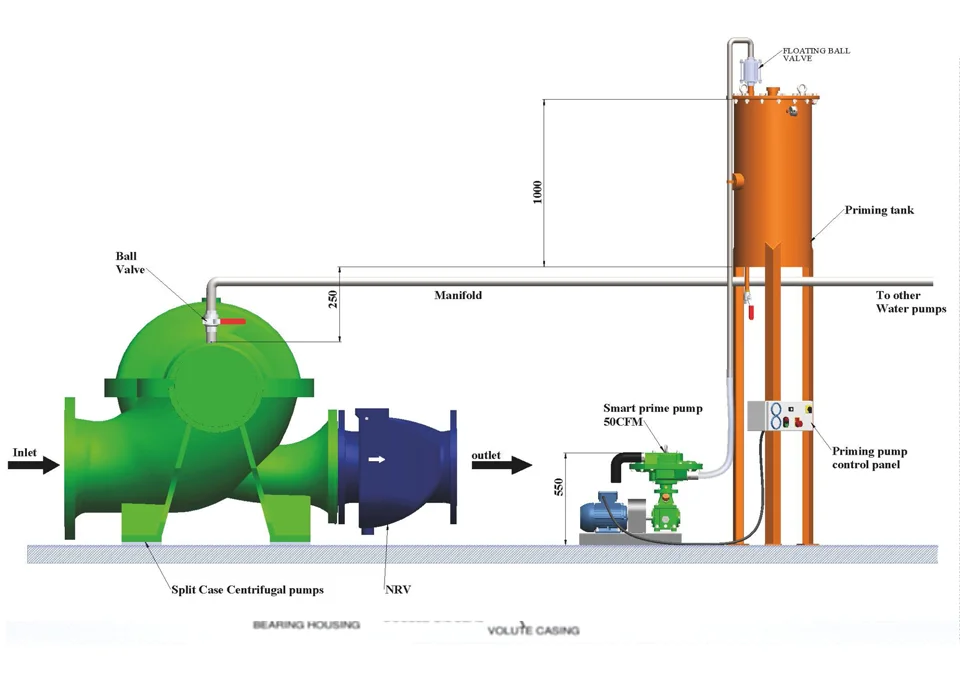

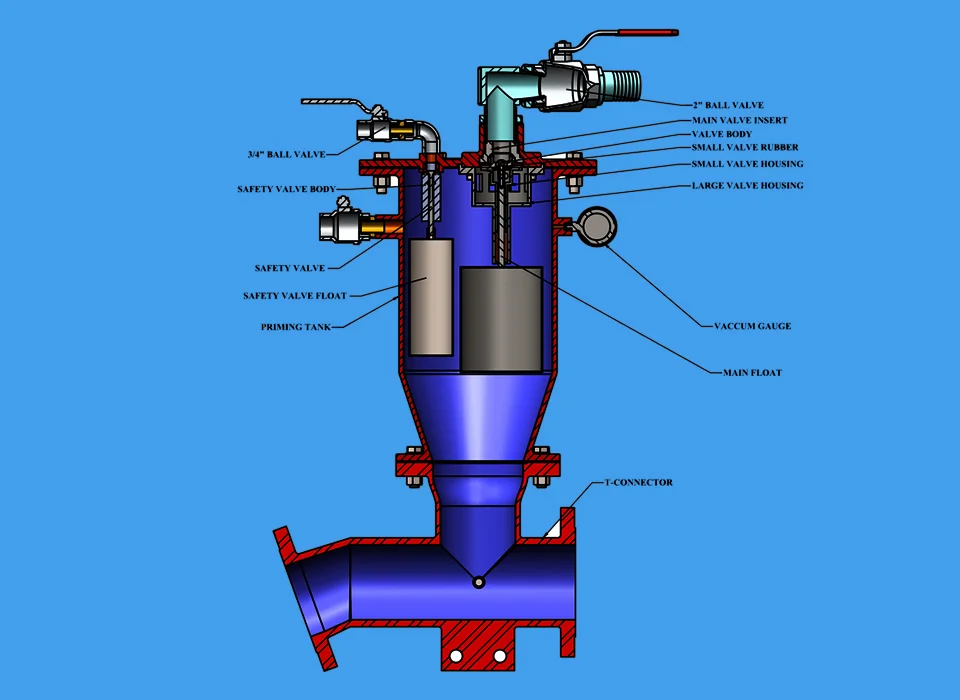

(50 Cfm @ 1200 RPM from Single Diaphragm Pumps & 100 Cfm @ 1200 RPM- Double Diaphragm Pumps) The priming system will create a vacuum in the pump and in the suction hose allowing the water to be drawn upwards towards the pump. After a short priming time the water will reach the main centrifugal pump and also enter the priming chamber of the priming tank. The float in the priming chamber will now raise when it reached approximately halfway up the chamber it will fits close the small value followed by closing of the large valve. The main centrifugal pump is now also pumping water through the system.

Status of the System

- Small valve is closed

- Large valve is closed

- Main float is highest position

- Non return valve on the pumps discharge is fully open

- Vacuum pump remains operating [Consumes very little power]

- System is now full of water

- Centrifugal pump is pumping water

Applications

If excess air accumulates in the priming chamber, a small valve will open to evacuate it before sealing again. In case of a sudden large influx of air, a larger valve will open for quicker evacuation. This priming system is clean, as it does not release oils into the environment. Importantly, no pumped fluids enter the vacuum pump; if they did, it could lead to pollution. This risk arises if dirt enters the valve system, causing leaks that draw fluids into the vacuum pump. Our Poseidon Smart Prime system includes a unique safety valve in the tank. If the water level gets too high, a secondary stainless steel float will allow air into the chamber, lowering the fluid level without affecting the centrifugal pump’s operation. This design prevents any fluid from entering the valve system or the priming pump.

Air and Water Separator

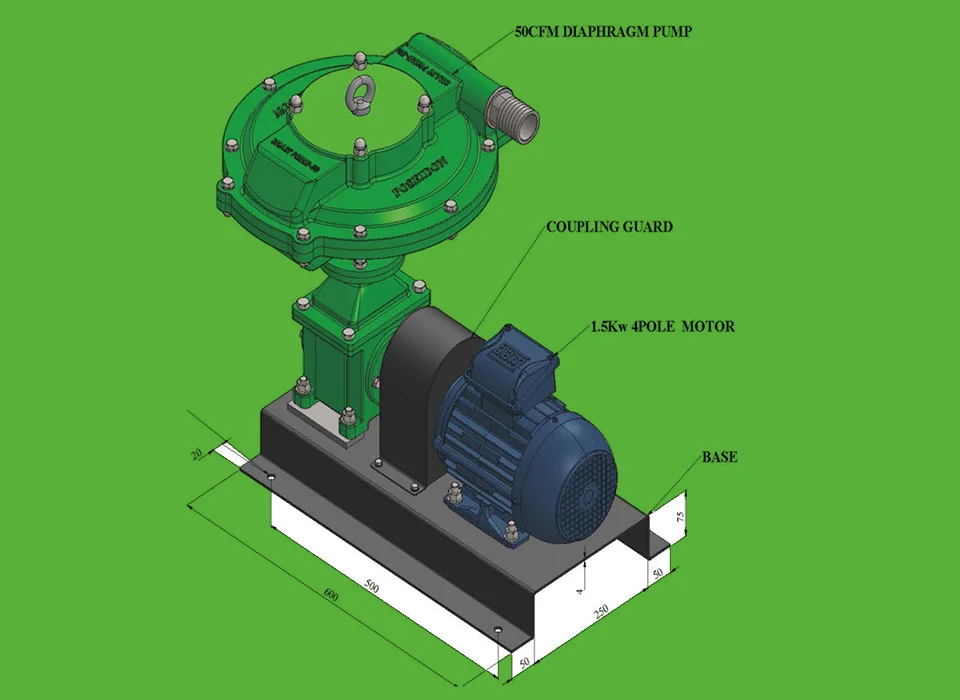

Electrical Driven 600-Pole

Dewatering Pumps with

Diaphragm Insulation